Why did the welding machine suddenly stop producing light, what are the direct reasons?

If the welding machine suddenly doesn't emit light, it may be due to the following direct reasons:

Power supply issue: Check if the power supply is normal, including stable voltage and good grounding.

Controller signal problem: Confirm if the controller's signals are normal, especially if the light out switch and safety interlock signals are showing green.

Laser issues: Check if the laser itself has any abnormal alarms or malfunctions, such as internal overheating or other anomalies.

Cooling system problem: Verify if the water cooling machine is operating properly, if the cooling water circuit is clear, and if the water temperature and flow rate are within normal ranges.

Air pressure issue: Ensure that the air pressure is normal, the gas supply is stable, and the gas valves are properly open.

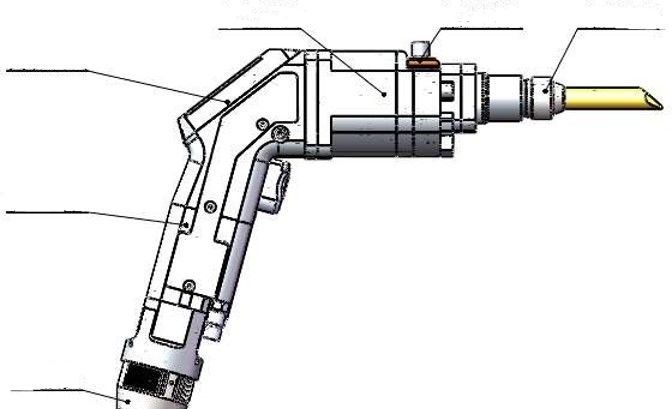

Lens issues: Check if the protective lens is clean, free of burn spots or other damages, and replace it if necessary.

If no issues are found in the above checks, it is recommended to contact technical support for further diagnosis and repair.

For further assistance, feel free to contact MSA Laser Co., Ltd. at: - Phone: 886-4-24263121 - Email: asia.laser@msa.hinet.net